Airplast case study: EDF’s Research and Development Center

29 September 2021

The EDF’s Research and Development Center is a 50,000 m2 complex designed for sustainable energy production research. It was built by our client, the Besix construction company, in the heart of the Paris-Saclay Campus.

These were the project’s primary goals and solutions:

Open space design

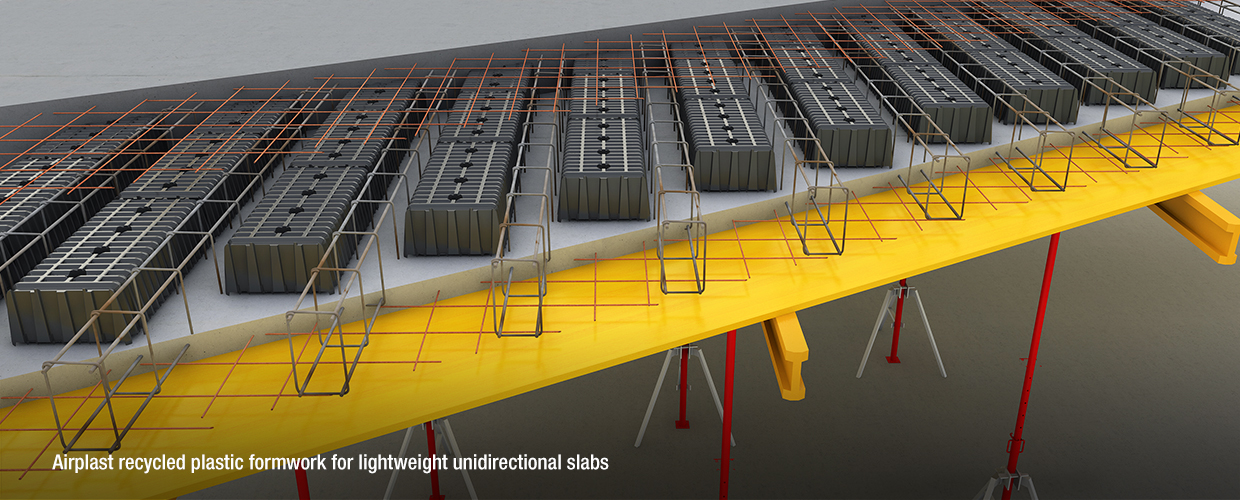

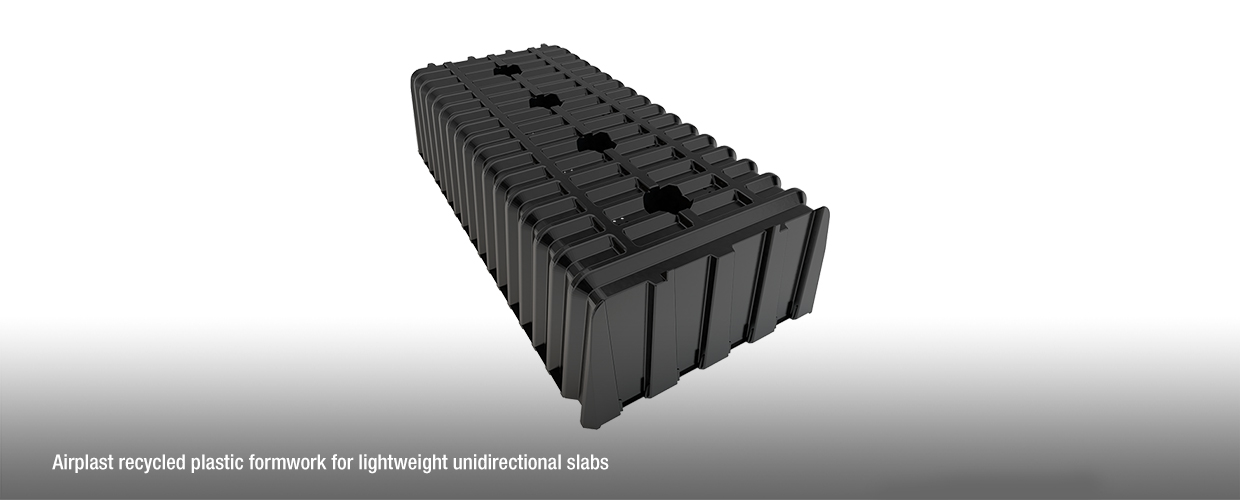

The main idea behind the EDF’s Research and Development Center design was to host different research teams in the same space and help them easily innovate by combining their expertise. This required an open-plan interior and large-span slabs. We recommended Aiplast formwork for the construction of lightened unidirectional slabs which reduced the use of concrete and lightened the slabs by 20 %. Lightened slabs allowed for fewer columns and structural walls, and a more open space design.

Sustainable profitability

The EDF Group is one of the major companies that is committed to achieving carbon neutrality by 2050. Airplast improved the sustainability of its Research and Development Center by reducing the use of EPS and concrete by 20 %. A decreased use of unsustainable materials led to a reduced need for transportation, worksite machinery, labor, and building time. This resulted in further improvement in sustainability and an overall cost reduction that increased the profitability of the project.

By using Airplast, our innovative solution for lightened slabs, our clients built the EDF’s Research and Development Center in a more sustainable and profitable way, enabling the successful cooperation of the academic research teams.

Learn more about Airplast or contact us.