Modulo family compared: features and differences

6 March 2024

Reduced transport, fast setup, less concrete

Dimensions: W50 / W71 cm, H13 – H70 cm

Application: foundations and slabs

Example project: Symbiosis Business District, Milan, Italy

Modulo consists of stackable recycled plastic modules that provide easy manual setup and reduced transport. It also reduces concrete usage by up to 20 %, lowering construction costs and CO2 emissions.

Even greater load capacity

Dimensions: W 71 cm, H13 – H40 cm

Application: foundations and slabs

Example project: Pacific Center, Panama City, Panama

Multimodulo consists of 4 Modulo elements molded together. In terms of sustainable profitability, it shares the same basic advantages as Modulo, along with an even greater load capacity due to the nine support pillars in each module.

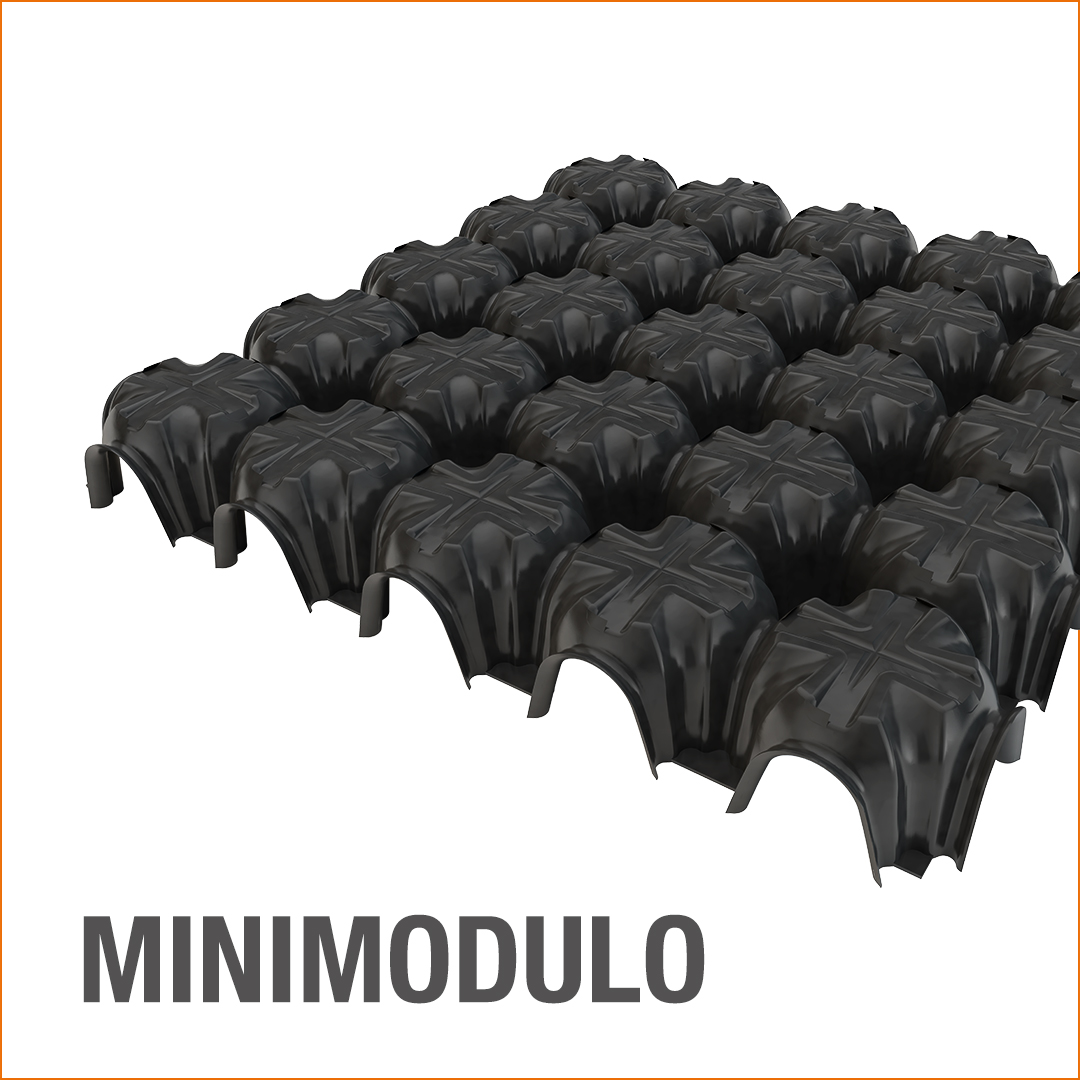

Material efficiency, reduced installation time

Dimensions: W50 / W58 cm, H3 – H9 cm

Application: floors, walls, roofs

Example project: St John’s Penthouse, Cape Town, South Africa

Minimodulo is the smallest in the Modulo family, measuring only 3 to 9 cm in height. This feature enables it to create ventilated spaces with minimal height requirements, reducing installation time and the need for wood and metal substructures in floors, walls, and roofs.