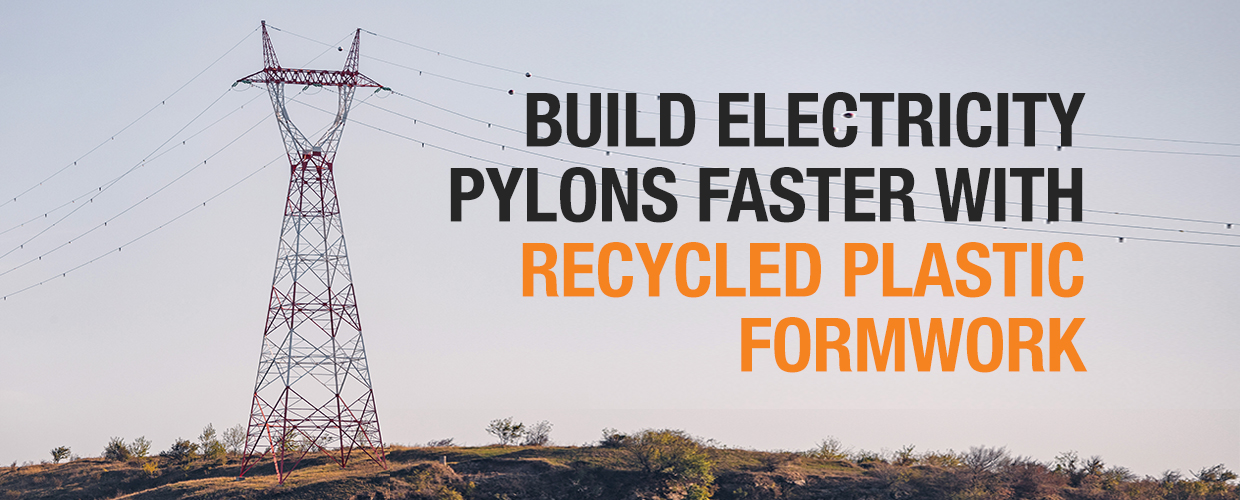

Build electricity pylon bases faster with recycled plastic formwork

7 August 2025

Pouring pylon bases in remote or confined locations is often slow with wood or metal formwork.

Recycled plastic formwork accelerates setup and makes moving from site to site easier.

Building concrete bases for electricity pylons often takes place in confined or hard-to-access locations, which can be slow and labor-intensive with wood and metal formwork. Geoplast recycled plastic formwork is designed specifically for difficult environments, allowing crews to pour pylon bases faster and move quickly to the next site. Here is how:

BUILD PYLONS FASTER

Weighing no more than 11 kg – Geotub from 3 to 10 kg, Geotub Panel up to 7 kg, and both Geopanel and Geopanel Star up to 11 kg – recycled plastic formwork is easy to handle manually in remote or uneven terrain where electricity pylons are built.

Ranging from 20 to 60 cm in width, the compact module sizes suit narrow access routes, forested areas, and hilly terrain typical of pylon sites, enabling crews to transport and assemble components quickly on site.

Using the same accessories and requiring no additional tools or mechanical equipment, recycled plastic formwork simplifies installation – ideal for off-grid or hard-to-reach pylon locations where speed and minimal specialized labor are essential.

Made from recycled plastic, Geoplast formwork can be reused over 100 times. Its smooth inner surface allows easy dismantling without release agents and quick cleaning with just water, enabling repeated use even in remote areas with limited supplies.

To build electricity pylons faster in your next project, contact Luca Zausa at luca.zausa@geoplastglobal.com or connect with him on Linkedin.